Overview

The design of the monopile foundations was carried out by UK engineering firm Atkins on behalf of Triton Knoll's lead contractor 3SF (a Smulders Sif Joint Venture). The design work represents an important progression within the offshore industry in the fabrication of lighter and more cost effective infrastructure; the modern design has saved the equivalent of over 3 Eiffel Towers worth of steel in the manufacturing process, while preserving the strength of the asset.

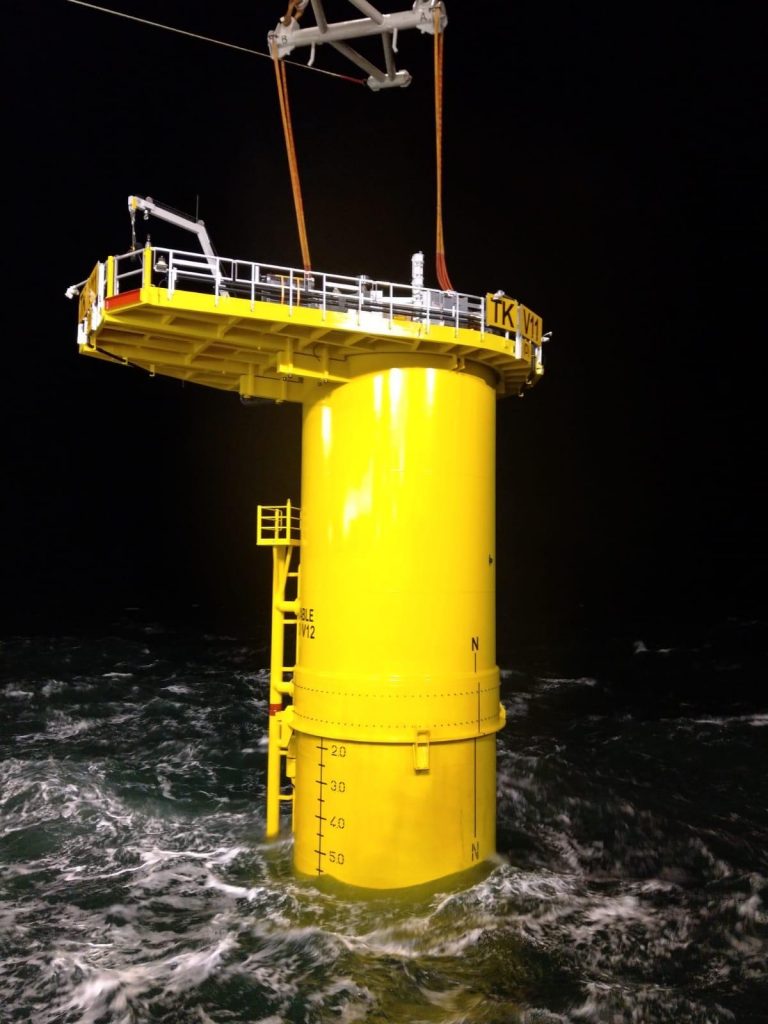

The transition pieces are the bright yellow sections that sit on top of the monopiles. The turbine towers, nacelles and blades are built on top of the transition pieces.

Installation of the foundations is being carried out by a specialist vessel called ‘Seaway Strashnov’, and which is operated by Seaway7. It first arrived on site in January 2020. The vessel is 183 metres in length and is capable of lifting up to 5,000 tonnes.

Principal Contractor: 3SF (design and supply); Seaway7 (transport and installation)

Expected completion: Q3 2020.

Progress Updates

On 19 August, Triton Knoll took another huge step towards first power generation in early 2021, completing the installation of all 90 monopile foundations and transition pieces, ready to receive the powerful MHI Vestas v164 9.5MW turbines early next year.

The successful delivery was achieved during one of the project’s most challenging times due to the impact of Covid19, and has been completed within the planned summer delivery window.

Throughout construction, the safety and welfare of everyone working on the project has been and remains a top priority for Triton Knoll and its contractors. Covid19 forced the implementation of significant changes in working practices, requiring regular screening and testing of personnel, long periods of isolation for many of those working on the project, and site and vessel lockdowns to ensure the safe and timely delivery of the critical energy infrastructure project could continue.

Project Director for Triton Knoll and RWE Renewables(1), Julian Garnsey, said “We are delighted to have completed this phase of construction within the summer delivery window despite the impacts of Covid19. This is a great credit to all of our supply chain partners and everyone working in the Triton Knoll team. We have made excellent progress on the project to date, and look forward to installation of the first offshore turbines in early 2021.”

Each foundation consists of a c.600 tonne steel monopile and c.160 tonne bright yellow transition piece, manufactured using state of the art methods to be significantly lighter than previous technologies. Innovative foundations design means that the steel savings in the manufacturing of the foundations is equivalent to 3.5 x Eiffel Towers, or 2 x Shard buildings, when compared with similar structures currently deployed offshore. The installation contract was awarded to, and managed by Seaway 7, and the foundations were installed by Heavy Lift Vessels Seaway Strashnov and DEME Innovation.

On 17 January, 2020, Triton Knoll safely and successfully installed the first of its 90 wind turbine monopile foundations, 32km off the Lincolnshire coast.

The c.600 tonne steel monopile and its bright yellow transition piece was installed by Seaway 7's (1) ‘Seaway Strashnov’ which is contracted to transport and install all 90 of the wind turbine foundations, as well as the two offshore substation platforms and their foundations.

The 'Strashnov' leads a fleet of vessels including the the high-tech Service Operation Vessel (SOV) ‘Esvagt Froude’ (2) operating out of Grimsby’s Royal Dock, in support of the construction of the wind farm.

The ‘Seaway Strashnov’ arrived on site at the beginning of January to install the turbine foundations, subject to weather conditions. The vessel is 183 metres in length and can lift up to 5,000 tonnes.

Each steel monopile weighs on average 600 tonnes and is around 54 metres long - longer and similar in width to the cabin of an Airbus A380 (3). The foundations design, by UK engineering firm Atkins on behalf of lead contractor 3SF (a Smulders Sif Joint Venture), represents an important innovation and has saved the equivalent of over 3 Eiffel Towers worth of steel in the manufacturing process, while preserving the strength of the asset.

(1) Seaway 7 is Subsea 7’s Renewables and Heavy Lifting business unit.

(2) Service Operation Vessels (SOV) are specially designed to support a continuous presence offshore, enabling crews to live for up to four weeks at a time in the field. The vessels improve efficiency and safety by reducing the need to travel from shore each day. The vessels have fully-fitted accommodation units and include a range of facilities to support onboard living.

(3) Airbus A380 dimensions - http://www.modernairliners.com/airbus-a380/airbus-a380-specs/